lv installations | Lv power cable method statement

$220.00

In stock

Low Voltage (LV) installations form the backbone of modern electrical infrastructure, delivering power to our homes, businesses, and industries. From the street transformer to the wall sockets we use daily, LV systems are critical for a reliable and safe electricity supply. This article delves into the intricacies of LV installations, covering LV distribution, method statements for LV installation and power cable installation, and highlighting the importance of professional expertise in ensuring a robust and compliant system.

What are LV Installations?

LV installations, as the name suggests, operate at low voltage levels, typically defined as 1000V AC or 1500V DC. These systems are responsible for distributing electricity from the medium voltage (MV) network to individual consumers. They encompass a wide range of components, including:

* Transformers: Step down the voltage from MV to LV levels.

* Distribution Boards (DBs): Centralized points for distributing power to various circuits.

* Circuit Breakers and Fuses: Provide protection against overcurrents and short circuits.

* Cables and Wiring: Conduct electricity throughout the installation.

* Switches and Sockets: Control the flow of electricity to appliances and equipment.

* Earthing Systems: Ensure safety by providing a path for fault currents to ground.

* Lighting Systems: Provide illumination for various environments.

* Control Systems: Manage and monitor the operation of the LV installation.

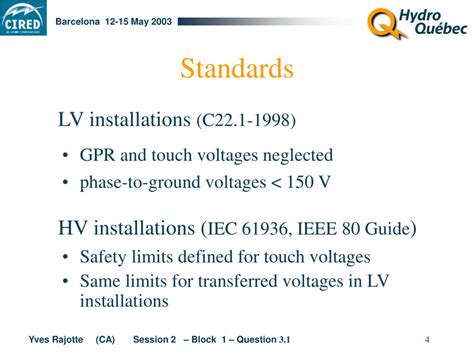

The design and installation of LV systems require a thorough understanding of electrical principles, relevant standards and regulations (e.g., IEC 60364, BS 7671 in the UK, NEC in the US), and best practices to ensure safety, reliability, and efficiency.

LV Distribution: The Arteries of Power

LV distribution refers to the network of cables, switchgear, and other equipment used to deliver power from the source (e.g., transformer) to the various loads within a building or facility. Effective LV distribution is crucial for minimizing voltage drops, reducing energy losses, and ensuring the reliable operation of connected equipment.lv installations

Key considerations in LV distribution include:

* Load Analysis: Accurately determining the power requirements of each load is essential for sizing cables and protective devices. This involves calculating the total connected load, diversity factors (to account for the fact that not all loads will operate simultaneously), and future load growth.

* Cable Sizing: Selecting the appropriate cable size is critical for minimizing voltage drops and preventing overheating. Factors to consider include the cable's current-carrying capacity, voltage drop limits, installation method (e.g., buried, in conduit, in free air), and ambient temperature.

* Protection Coordination: Circuit breakers and fuses must be coordinated to ensure that the fault closest to the load is cleared first, minimizing disruption to the rest of the system. This involves selecting devices with appropriate time-current characteristics and ensuring that they are properly installed and maintained.

* Earthing System Design: A properly designed earthing system is essential for safety, providing a low-impedance path for fault currents to ground. The type of earthing system (e.g., TN-S, TN-C-S, TT, IT) depends on the specific application and local regulations.

* Voltage Regulation: Maintaining a stable voltage level is crucial for the reliable operation of sensitive equipment. Voltage regulation can be achieved through various means, such as using automatic voltage regulators (AVRs) or selecting cables with low impedance.

* Harmonic Mitigation: Non-linear loads, such as variable frequency drives (VFDs) and electronic ballasts, can generate harmonics that can distort the voltage waveform and cause problems with other equipment. Harmonic filters may be required to mitigate these effects.

* Power Quality Monitoring: Regularly monitoring power quality parameters, such as voltage, current, frequency, and harmonics, can help identify potential problems and prevent equipment failures.

Method Statement of LV Installation: A Blueprint for Safety and Compliance

A method statement is a document that outlines the step-by-step procedures for carrying out a specific task, in this case, LV installation. It is a crucial tool for ensuring safety, compliance with regulations, and quality workmanship. A well-written method statement should include the following:

* Introduction: Clearly define the scope of the work and identify the location of the installation.

* Objectives: State the goals of the installation, such as providing a reliable and safe power supply to a specific area.

* References: List all relevant standards, regulations, and manufacturer's instructions.

* Personnel: Identify the personnel responsible for carrying out the work and their qualifications. This includes electricians, supervisors, and safety officers.

* Tools and Equipment: List all tools and equipment required for the installation, including testing equipment and personal protective equipment (PPE).

* Materials: Specify the types and quantities of materials to be used, such as cables, conduits, circuit breakers, and earthing materials.

* Risk Assessment: Identify potential hazards associated with the installation and outline the control measures to be implemented. This should include hazards related to electrical shock, falls from height, manual handling, and working in confined spaces.

* Step-by-Step Procedure: Provide a detailed description of each step involved in the installation, including:

Additional information

| Dimensions | 9.8 × 1.6 × 2.9 in |

|---|